Introduction

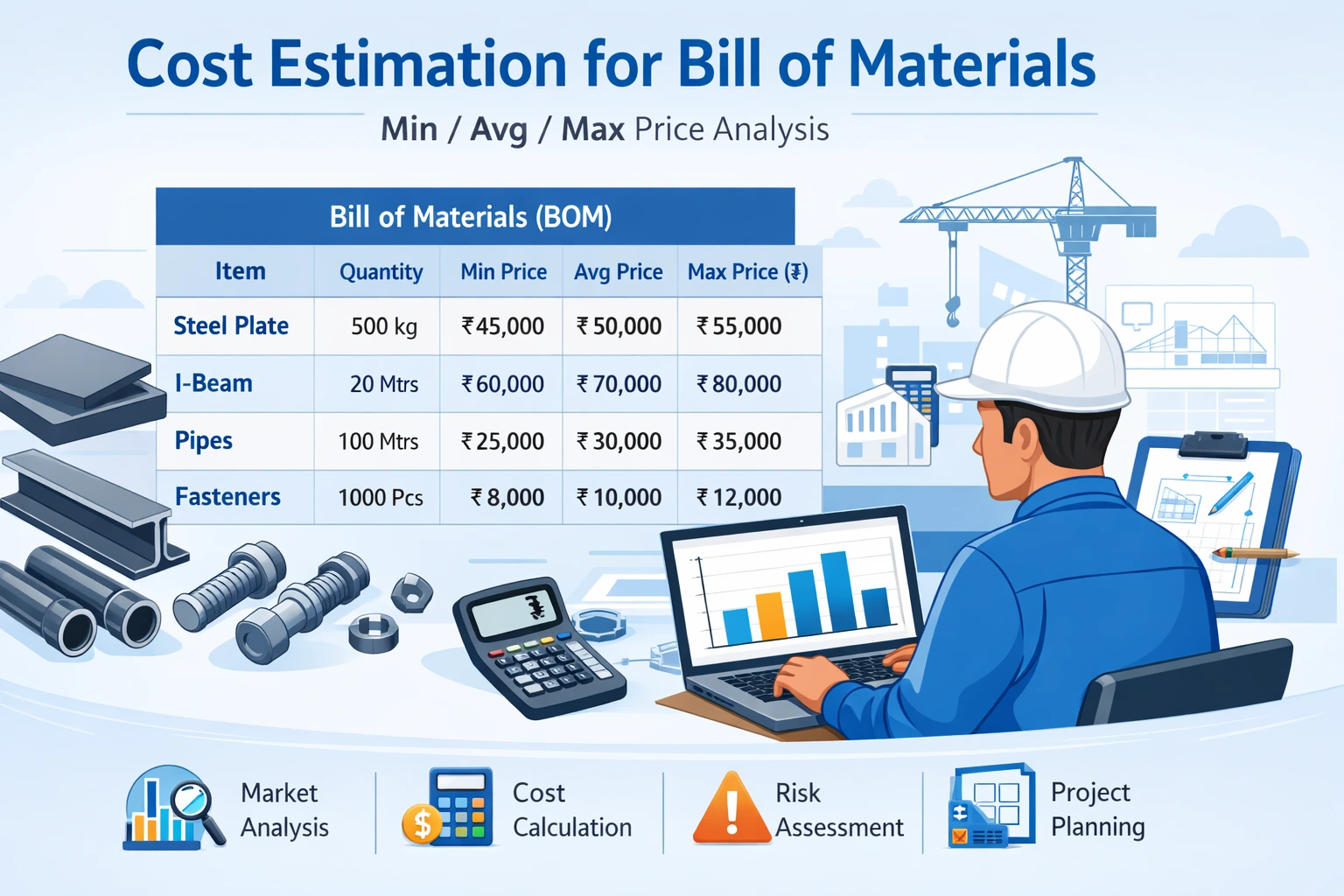

Accurate cost estimation starts with a well-prepared Bill of Materials (BOM).

However, in real-world projects, material prices fluctuate due to market volatility, supplier variation, and logistics costs.

Therefore, estimators use price range estimation methods instead of fixed prices.

This article explains the most reliable BOM price range estimation methods, their formulas, and practical fabrication examples to help estimators, project managers and cost engineers make informed decisions.

What Is BOM Price Range Estimation?

BOM price range estimation is a technique where material costs are calculated using minimum, average, and maximum price limits instead of a single value.

Why Price Range Estimation Is Important

Price range estimation is important because material costs are not fixed and often change due to market fluctuations, supplier differences, transportation and taxes.

Using a price range instead of a single rate helps estimators in many ways like:

- Manage uncertainty

- Handles steel price fluctuations

- Reduce the risk of cost overruns and

- Prepare more realistic project budgets.

- Helps management approve budgets with confidence

It also supports better decision-making during tendering and improves cost control throughout the project lifecycle.

BOM Estimation Techniques

Accurate Bill of Materials (BOM) estimation requires selecting the right technique based on project stage, data availability and risk level.

Using the right BOM estimation technique improves cost accuracy, reduces financial risk, and supports confident project decision-making.

Try Our Free Online Cost Estimation Calculator

Instantly calculate material, labor, overhead, GST, and profit for your project with RK Estimation tools.

In practice, a combination of methods delivers the most reliable BOM cost estimate.

Below are the most widely used BOM estimation techniques, explained in detail with practical context.

1. Historical Data–Based Estimation

This technique uses material cost data from previous similar projects as a reference.

How it works

- This method uses past project material prices as reference.

- Analyze past BOMs for similar size, scope, and material type

- Adjust prices for inflation, location, and market trends

Formula

Estimated Price Range = Historical Price ± Price Variation (%)

Example (Fabrication): Historical MS Plate Price: ₹65/kg & Expected variation: ±10%

Estimated Range: ₹58.50/kg to ₹71.50/kg

Advantages |

Limitations |

Best used when |

| Quick and easy to apply | Less accurate if market conditions change significantly | Project scope is similar to completed projects or Similar projects executed recently |

| Reliable for repeat or standardized projects | Limited time is available for estimation. Stable suppliers available |

2. Supplier Quotation Range Method

Material prices are estimated using multiple vendor quotations.

How it works

- Multiple vendor quotations are collected to define the price range.

- Collect minimum 3 quotations for each BOM item

- Define Min, Avg, and Max price range

Formula

Price Range = Lowest Quote to Highest Quote

Example:

| Supplier | Price (₹/kg) |

|---|---|

| Vendor A | 68 |

| Vendor B | 72 |

| Vendor C | 75 |

BOM Price Range: ₹68 – ₹75/kg

Advantages |

Limitations |

Best used when |

| High accuracy and High reliability for tendering | Time-consuming | Tendering and final budgeting stage |

| Reflects current market conditions. High reliability for tendering | Quotes may change before order placement |

3. Parametric Estimation Technique

This method estimates material cost using unit-based parameters such as weight, length, or area.

How it works

Cost is estimated using price per unit weight, length or area.

Formula

Material Cost = Quantity × Rate Range (₹/kg, ₹/m, ₹/m²)

Example:

Structural Steel Weight: 12,000 kg & Rate Range: ₹64 – ₹70/kg

Cost Range: ₹7.68 lakh – ₹8.40 lakh

Advantages |

Limitations |

Best used when |

| Fast estimation for large BOMs | Less detailed | Conceptual or feasibility stage |

| Suitable for early-stage planning and Early project budgeting | Requires reliable unit rates | Concept-level estimation |

4. Three-Point (PERT) Estimation Technique

Uses three price scenarios to calculate a statistically weighted expected cost.

How it works

A statistically reliable method using optimistic, most likely and pessimistic prices.

Inputs

Optimistic (Minimum price)

Most likely (Average price)

Pessimistic (Maximum price)

Formula

Expected Cost = (Min + 4×Avg + Max) / 6

Example:

Optimistic Price: ₹62/kg, Most Likely: ₹66/kg, Pessimistic: ₹72/kg

Expected Price: ₹66.7/kg

Advantages |

Limitations |

Best used when |

| Accounts for uncertainty and risk | Requires experience to define price ranges | High-risk projects |

| More realistic than single point estimates | Long duration projects |

5. Index-Based Price Escalation Technique

Used when material prices are expected to change over time.

How it works

Base material price is adjusted using official price indices

Formula

Revised Price = Base Price × (Current Index / Base Index)

Example:

Base Steel Price: ₹60/kg

Base Index: 210

Current Index: 235

Revised Price: ₹67.14/kg

Advantages |

Limitations |

Best used when |

| Ideal for long-term contracts | Depends on availability of reliable indices | Infrastructure and EPC projects |

| Reduces escalation disputes | Long-term contracts |

6. Contingency-Based Estimation

Adds a risk buffer to the estimated BOM cost.

How it works

Adds risk buffer to BOM pricing.

Apply contingency percentage based on risk assessment

Formula

Final Price Range = Base Estimate ± Contingency (%)

Typical Range

Low risk: 3–5%

Medium risk: 5–10%

High risk: 10–15%

Example:

Base Estimate: ₹80 lakh

Contingency: ±8%

Final Range: ₹73.6 – ₹86.4 lakh

Advantages |

Limitations |

Best used when |

| Protects against unforeseen price changes | Overestimation if contingency is excessive | Final budget approval stage |

7. Hybrid BOM Estimation Approach (Best Practice)

Combines multiple techniques for higher accuracy.

Example

Historical data for base rate

Supplier quotes for validation

Three-point estimation for risk handling

Benefits

Balanced accuracy and risk control

Preferred for professional estimation

Comparison Table of BOM Price Range Estimation Methods

| Method | Accuracy | Risk Handling | Best Stage |

|---|---|---|---|

| Historical | Medium | Low | Budgeting |

| Supplier Quotes | High | Medium | Tender |

| Parametric | Medium | Medium | Concept |

| Three-Point | High | High | Planning |

| Index-Based | High | High | Long-term |

| Contingency | Medium | High | Final Estimate |

Best Practices for Accurate BOM Price Range Estimation

Update steel & material rates monthly

Maintain a price history database

Use multiple estimation methods together

Always include taxes, freight & wastage

Automate BOM estimation using calculators

FAQs

It is a method of estimating material costs using minimum, average and maximum price limits.

Supplier quotation and three-point estimation methods provide the highest accuracy.

Fixed prices fail to account for market fluctuations and increase project risk.

Conclusion

Using BOM price range estimation methods help project teams manage uncertainty, improve budgeting accuracy, and reduce financial risk. Combining historical data, supplier inputs, and statistical techniques ensures reliable cost forecasting in fabrication and construction projects.