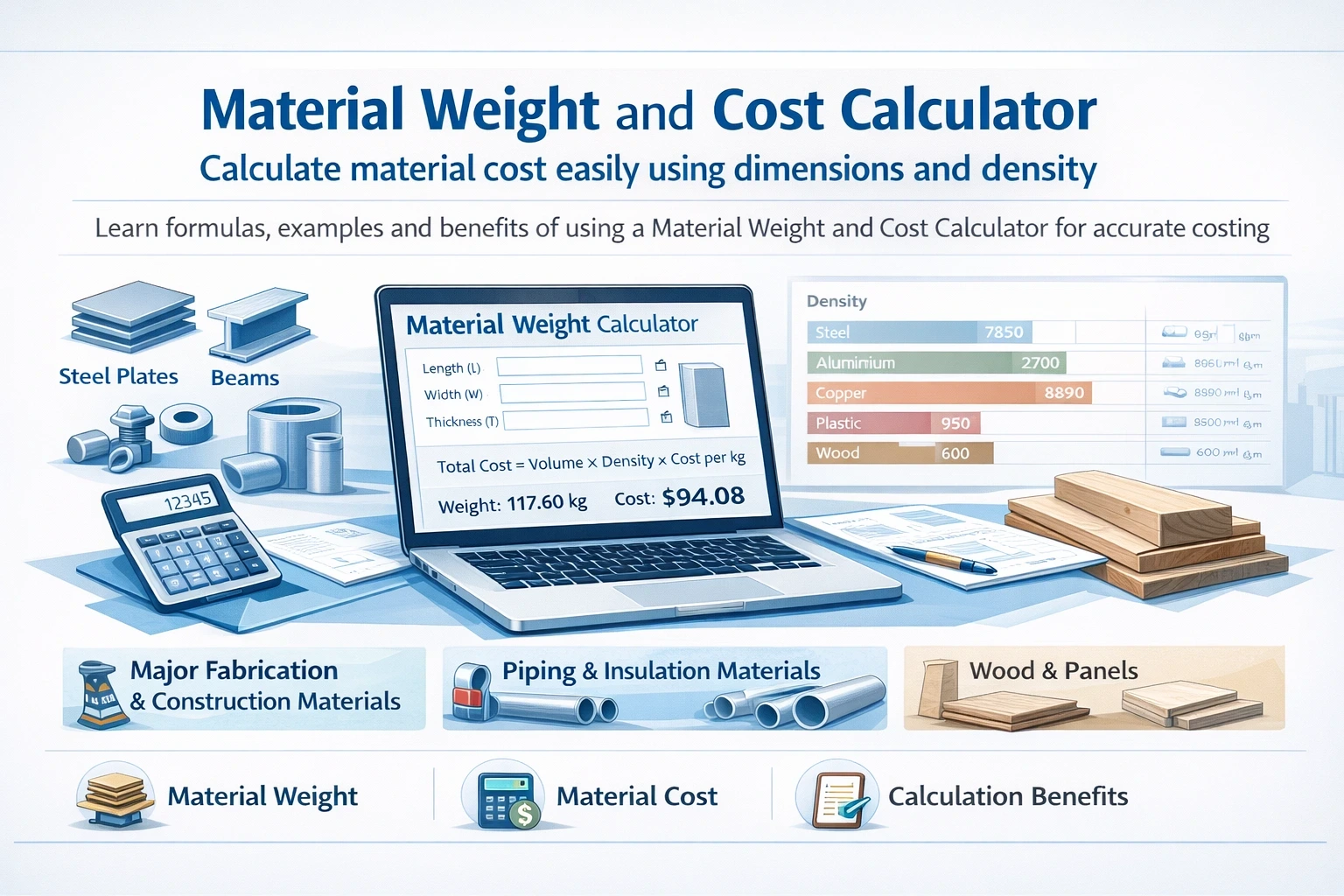

What is a Material Weight and Cost Calculator?

A Raw Material weight and Cost Calculator is an online or software-based tool used to compute the cost of Materials like steel MS, SS or Aluminium plates by using thickness, width, length and density of that material.

This calculator eliminates manual calculation errors and simplifies material costing.

This blog guide and explains what material cost calculation is, why it important, formulas used, and how to calculate cost of materials step-by-step.

Accurate material calculation is essential for material

planning, cost estimation, procurement and project budgeting.

A Material Weight and Cost Calculator help engineers, fabricators, contractors, and estimators quickly determine the cost of Material based on dimensions, material density and Material market price.

Material Weight and Cost Calculation Formula

The standard formula used to Calculate weight of Material in Kg and Multiply it with market price:

Weight (kg) = Length (mm) × Width (mm) × Thickness (mm) × Density (kg/m³)

Weight (kg) = (L × W × T × Density) ÷ 1,000,000,000

Cost (₹) = Weight (kg) × Rate per kg

For steel, density ≈ 7850 kg/m³

How to Use this Online Material Cost Calculator

Step 1: Enter Size of Material

- Length (in mm)

- Width (in mm)

- Thickness (in mm)

Step 2: Enter Density of Material Type

- Mild Steel (MS)

- Stainless Steel (SS)

- Carbon Steel

- Alloy Steel

Step 3: Enter Material Market Price

Below are the Most Used Densities (This if for Quick Reference for Estimators)

Steel: 7850 kg/m³

Concrete: 2400–2500 kg/m³

Aluminium: 2700 kg/m³

Copper: 8960 kg/m³

Brickwork: 1800 kg/m³

Step 4: Get Instant Result

Density of Major Fabrication & Construction Materials (kg/m³)

1. Metals (Fabrication Use)

| Material | Density (kg/m³) |

|---|---|

| Mild Steel (MS) | 7850 |

| Carbon Steel | 7850 |

| Stainless Steel (SS 304 / 316) | 7900 – 8000 |

| Cast Iron | 7200 – 7300 |

| Aluminium | 2700 |

| Copper | 8960 |

| Brass | 8400 – 8700 |

| Bronze | 8800 – 8900 |

| Zinc | 7130 |

| Lead | 11340 |

2. Construction Materials

| Material | Density (kg/m³) |

|---|---|

| Plain Cement Concrete (PCC) | 2400 |

| Reinforced Cement Concrete (RCC) | 2500 |

| Cement | 1440 |

| Sand (Dry) | 1450 – 1600 |

| Sand (Wet) | 1700 – 1900 |

| Coarse Aggregate | 1500 – 1700 |

| Brick Masonry | 1800 – 2000 |

| AAC Blocks | 550 – 700 |

| Fly Ash Bricks | 1700 – 1800 |

| Stone (Granite/Basalt) | 2600 – 2800 |

3. Piping & Insulation Materials

| Material | Density (kg/m³) |

|---|---|

| PVC | 1380 – 1450 |

| HDPE | 940 – 970 |

| Rubber | 1100 – 1200 |

| Glass Wool | 12 – 48 |

| Rock Wool | 40 – 200 |

| PU Foam | 30 – 50 |

4. Wood & Panels

| Material | Density (kg/m³) |

|---|---|

| Timber (Teak) | 650 – 750 |

| Plywood | 500 – 700 |

| MDF Board | 700 – 850 |

| Particle Board | 600 – 750 |

Who Uses This Calculator?

- Costing and Estimation professionals

- Fabricators & welders

- Contractors & builders

- Procurement professional

- Structural and Mechanical engineers

- Students and Graduate Engineers

- Production & manufacturing professionals

Benefits of Using a Material Cost Calculator

- Saves time and improves accuracy during tendering and estimation.

- Ideal for fabrication costing who work on Kg Basis

- Reduces human error while cost calculation

- Helps during procurement cost calculation

- Useful for logistics, Vehicle loading planning & billing material on kg basis.

Conclusion

A Material Weight and cost Calculator is a quick and precise tool to compute Material weight and cost of all kinds of martial for estimation and costing.

Whether you're estimating material weight or cost, using a calculator ensures accuracy and efficiency.

Add this tool to your workflow to streamline your material weight and cost calculation.