What is Sheet Metal Bending Costing?

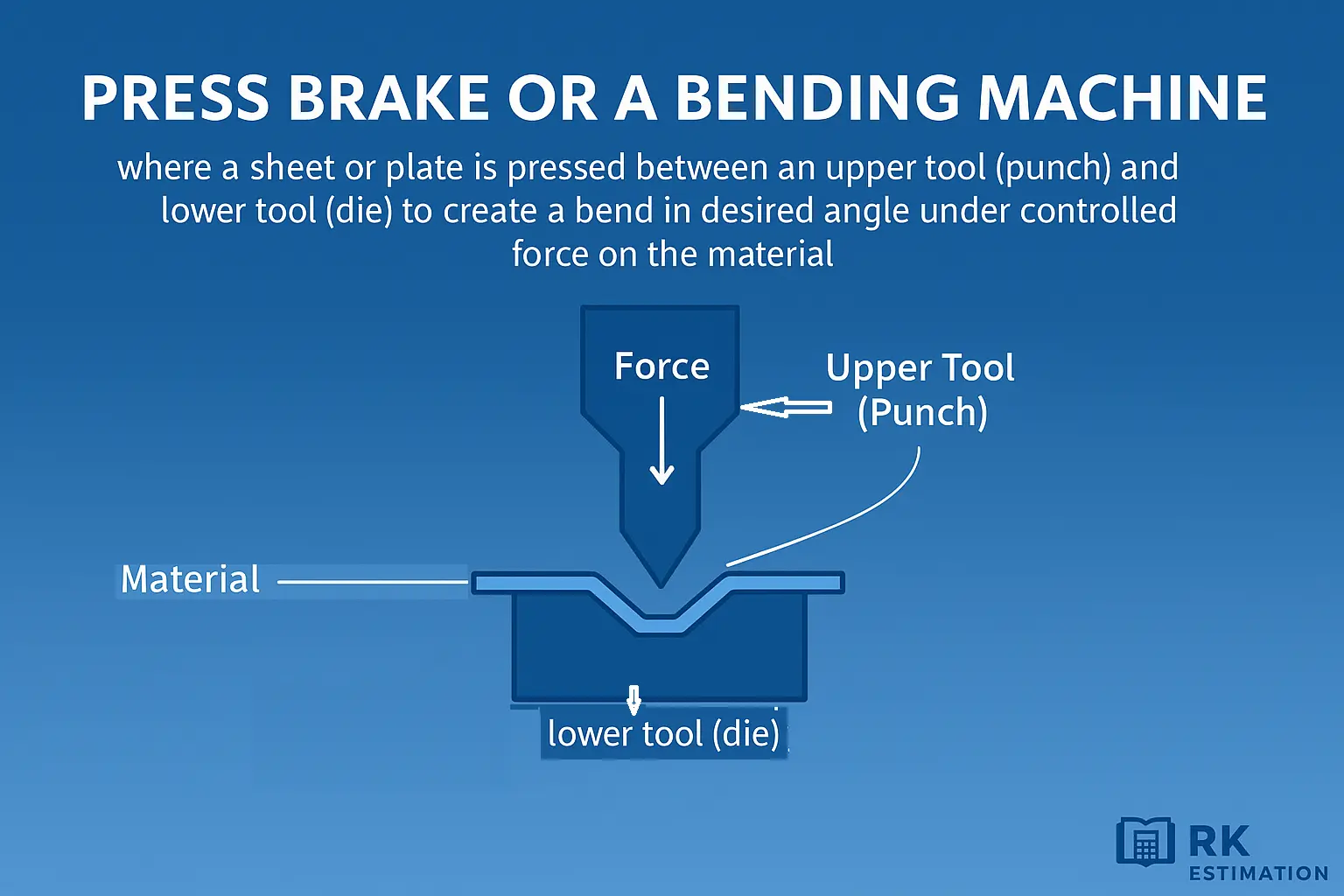

Sheet metal bending is one of the most common processes of shaping a metal sheet into desired angle and geometry by applying force to form a shape.

It is a manufacturing method which is done in a press brake or a bending Machine where a sheet or plate is pressed between an upper Tool (Punch) and lower tool (Die) to create a bend in desired angle under controlled force on the material.

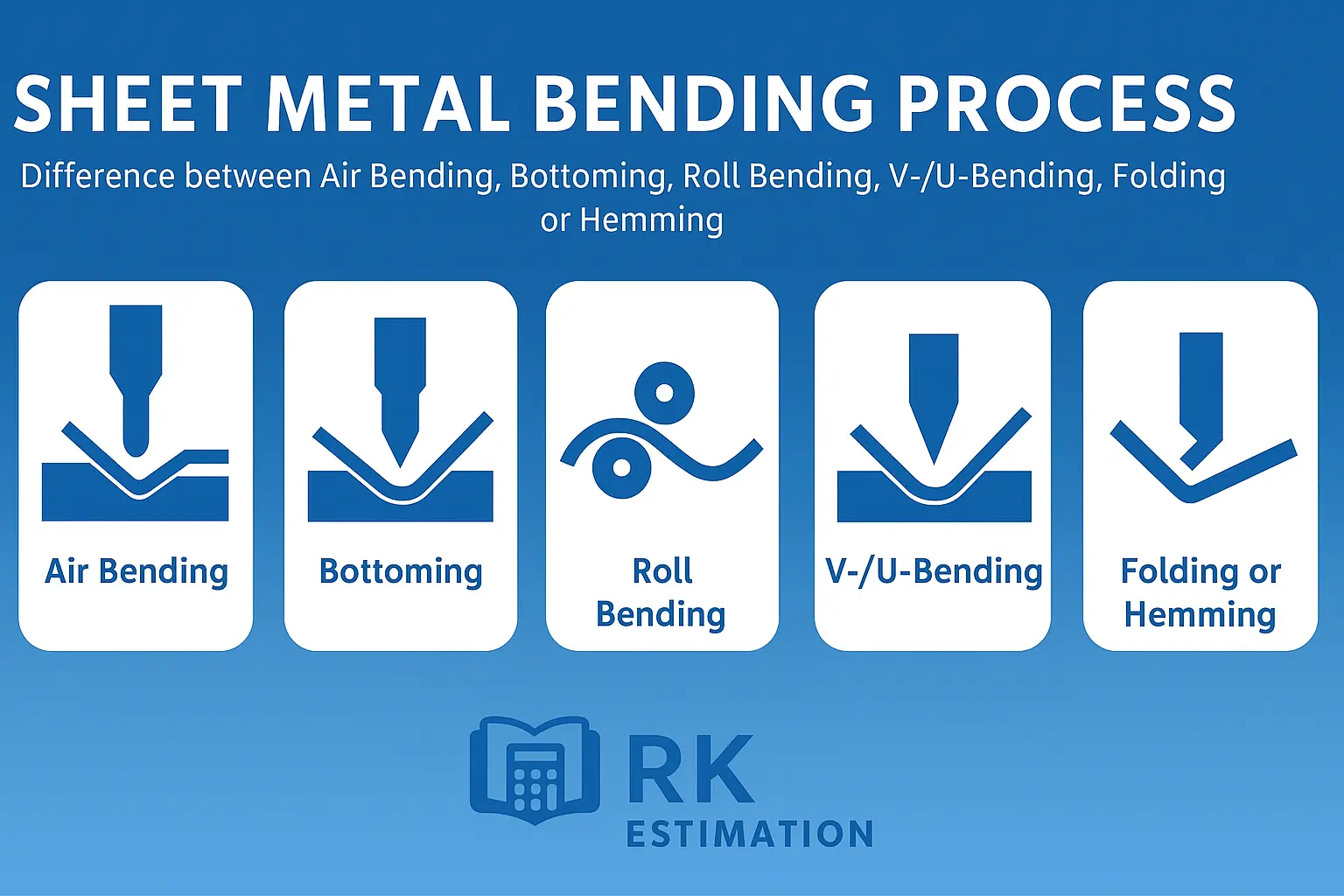

Types of Sheet Metal Bending, Difference and Their Cost Impact

Below are the different Type of bending methods which affect the cost due to

tooling complexity, accuracy, and machine time.

1. Air Bending (Cost: Low to medium)

It is most common and cost-effective method in which sheet is bend by pressing it against a V-Shape die and the punch presses the sheet partially into the die which provide flexibility for different angles and require less force.

2. Bottoming (Coining or Bottom Bending) (Cost: High)

In this method the sheet is pressed fully down into the die cavity until it takes the exact shape. It provides high accuracy and repeatability, but it requires more force and setup time.

3. Roll Bending (Cost: Medium to high)

This method is used for creating rounded shape, large radius or cylindrical shapes by passing the sheet between three roller machines. Example: tanks, drums, and curved panels.

4. V-Bending / U-Bending (Cost: Low to medium)

This is Standard process for forming V or U shapes on press brakes. It requires quick setup and moderate precision.

5. Folding or Hemming (Cost: Medium)

This is a secondary operation this process used for folding sheet edges for safety, appearance, or reinforcement.

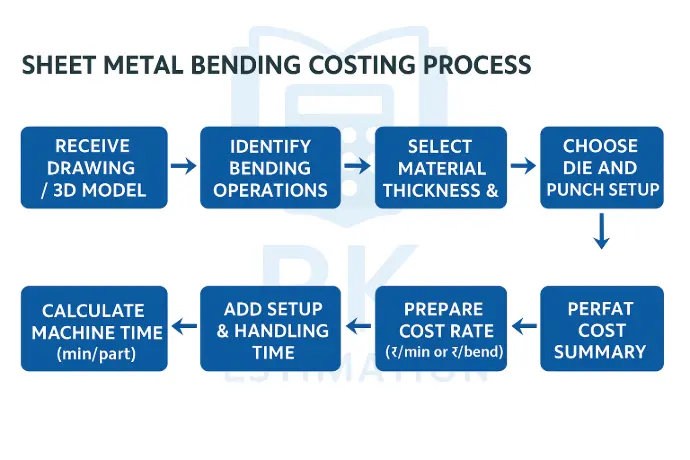

Sheet Metal Bending Costing Process Steps:

Receive Drawing / 3D Model

Identify Bending Operations

Select Material Thickness & Type

Determine Bend Length & Angle

Choose Die and Punch Setup

Calculate Machine Time (min/part)

Add Setup & Handling Time

Apply Cost Rate (₹/min or ₹/bend)

Prepare Cost Summary / Quotation

Factors influencing Sheet metal bending cost:

Bending costing helps to determine the total price to form a sheet metal part efficiently and profitably. The cost of sheet metal bending depends on many variables:

1. Material Type

Material Type (Mild steel, Stainless steel Aluminum etc.) affect cost as selection of Machine is required.

2. Material Grade

Grade (E250/E350/E450 etc.) Low grade easy bend high grade more time and precision required to prevent crack.

3. Material Thickness

Higher thickness required high force and more time which will increase cost.

4. Number of bends in Part

Each bend required additional stroke which will increase bending time and setup cost

5. Bend Angle

Simple bend angle requires less time, but complex shape require multiple bend and setting.

6. Type of Machine

Machine setup and operation: CNC Machine require less setup time and operation time but high machine our rate than Conventional machine.

7. Tool selection and setting

Standard tool is more cost effective. Special tool for certain bend will increase price.

8. Batch or Lot size

Small lot size or prototype have high unit cost as big lot size set up time will spread over more unit.

9. Tolerance Requirement

High tolerance cost increases due to precise setup and frequent measurement.

10. Post processing requirement

Post processing like grinding, sharp edge removal, any other operation like drilling or surface treatment can increase cost.

11. Labor and handling cost

12. Tooling and die wear and maintenance cost

13. Power consumption

14. Overheads and profit margins

How to Optimize the Cost of Sheet metal bending cost

1. Design with minimum thickness variation and minimum no. of bend.

2. Design with standard angle to avoid special tool

3. Plan production Order in lot size.

4. Proper Machine and tool selection to minimize force

5. Use optimal material as per application.

Conclusion

Sheet metal bending costing is more than just a financial estimate. It is a decision-making tool that ensures cost effective method for shaping sheets.

Accurate costing helps in:

- Prepare accurate fabrication quotations

- Pricing jobs competitively

- Reducing waste and rework

- Optimize resources and reduce rework

- Improve overall production efficiency

By mastering sheet metal bending costing, you can ensure precision, profitability, and productivity in every fabrication project.