Machining is one of the most widely used manufacturing processes—essential for shaping metals and components with precision.

Understanding the costing of machining processes is essential for accurate pricing, efficient production, and better resource planning.

This guide explains the meaning, types, and key cost components of machining, helping manufacturers control expenses, improve productivity, and ensure high-quality output.

This guide explains why accurate costing is crucial in today’s competitive fabrication and manufacturing industries.

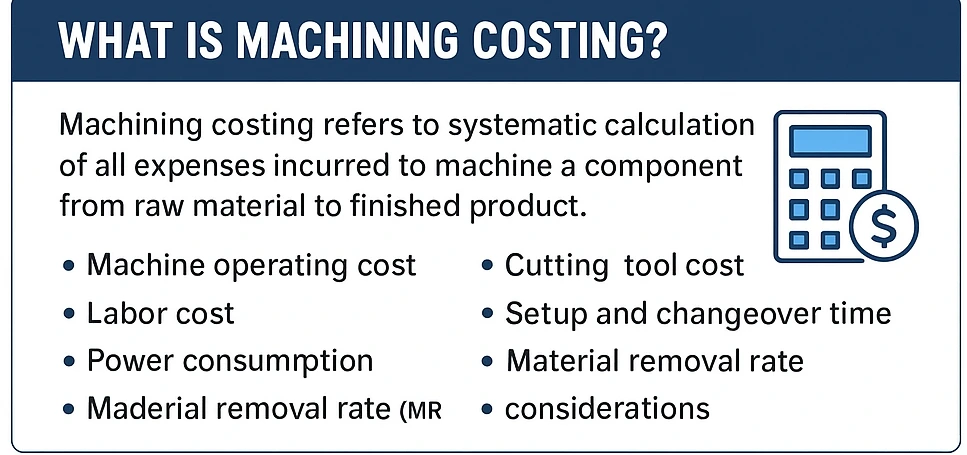

What Is Machining Costing?

Machining costing refers to the systematic calculation of all expenses incurred to machine a component from raw material to finished product.

It includes:

- Machine operating cost

- Cutting tool cost

- Labor cost

- Setup and changeover time

- Power consumption

- Material removal rate (MRR) considerations

- Depreciation and overheads

Proper machining cost estimation ensures the component is manufactured economically while maintaining required tolerances and quality.

Types of Machining Processes Considered in Costing

Costing varies based on the machining method used.

Key machining types include:

1. Turning

Performed on a lathe to remove material from a rotating workpiece. Costs depend on cutting speed, feed, part diameter, and tool life.

2. Milling

Removes material using a rotating cutter. Cost influenced by machine power, number of passes, tooling, and setup time.

3. Drilling

Used to create holes; cost depends on diameter, depth, and cycle time.

4. Boring

Internal enlargement of holes; generally costlier due to precision tooling.

5. Grinding

High-precision finishing process; cost includes wheel wear and slower MRR.

6. CNC Machining

Automated machining with higher accuracy and higher machine hourly rates; cost depends on program complexity and cycle time.

7. Shaping & Planning

Used for flat surfaces; cost is based on stroke length and machine output.

8. Broaching

Fast process but involves expensive broach tools, affecting cost structure.

Key Cost Components in Machining

To estimate machining cost accurately, the following factors must be considered:

1. Machine Hourly Rate

Includes depreciation, maintenance, interest, and operating expenses.

2. Labor Cost

Operator wages, skill level, and supervision requirements.

3. Tooling Cost

Tool wear rate, tool life, re-sharpening, and replacement cost.

4. Setup Cost

Fixture preparation, part alignment, and tool change time.

5. Cutting Parameters

MRR, spindle speed, feed rate, and depth of cut, which directly affect cycle time.

6. Power Consumption

Electricity usage based on machine load and cycle duration.

7. Overheads

Indirect factory expenses distributed per hour or per part.

8. Inspection & Quality Cost

Accuracy checks, CMM measurements, and rejection/rework cost.

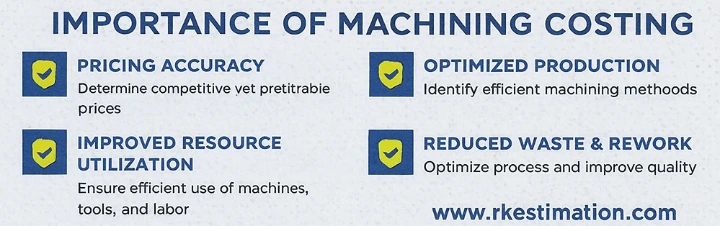

Importance of Machining Costing

Machining costing plays a vital role in manufacturing for several reasons:

✔ Pricing Accuracy

Helps determine competitive yet profitable selling prices.

✔ Optimized Production

Identifies the most cost-effective machining method and parameters.

✔ Improved Resource Utilization

Ensures machines, tools, and manpower are used efficiently.

✔ Better Job Planning & Scheduling

Accurate time and cost estimation helps in forecasting delivery timelines.

✔ Reduced Waste & Rework

By understanding cost drivers, manufacturers can optimize processes and improve quality.

✔ Budgeting & Cost Control

Supports financial planning, profitability analysis, and continuous improvement.

Conclusion

Accurate costing of machining processes is essential for maintaining profitability, improving productivity, and achieving consistent product quality. Whether you are performing turning, milling, drilling, or CNC machining, understanding the cost components involved empowers manufacturers to make informed decisions and stay competitive.