Bevel cost analysis plays a major role. For manufacturers, fabricators, and engineering professionals, understanding the costing of beveling operations is essential for accurate estimation, budgeting, and competitive bidding.

Common industries using beveling include:

- Pressure vessel fabrication

- Pipeline construction

- Shipbuilding

- Heavy machinery manufacturing

- Structural steel fabrication

What Is Material Beveling?

Meaning of beveling: Material beveling is the machining or cutting of a material edge. It is a critical preparatory process used across fabrication industries to create angled edges on metal plates, pipes, and structural components.

Importance of beveling-

- Bevels are used to prepare surfaces for welding. These angled cuts improve weld penetration, reduce defects, and increase the strength and quality of welded joints.

- Remove sharp edges for handling safety, and achieve design aesthetics or functional requirements

Types of Material Bevels

- 1. V-Bevel- A straight-angle bevel used for typical weld preparations (e.g., 30°, 35°, 45°).

- 2. J-Bevel-Curved bevel that reduces filler metal consumption; common in thick plates and piping.

- 3. U-Bevel-Symmetrical curved edges used for high-strength weld joints.

- 4. Compound Bevel-Combination of two angles, often for complex welding requirements.

- 5. Pipe Beveling-Beveling cylindrical components for pipeline welding, often performed using portable beveling machines.

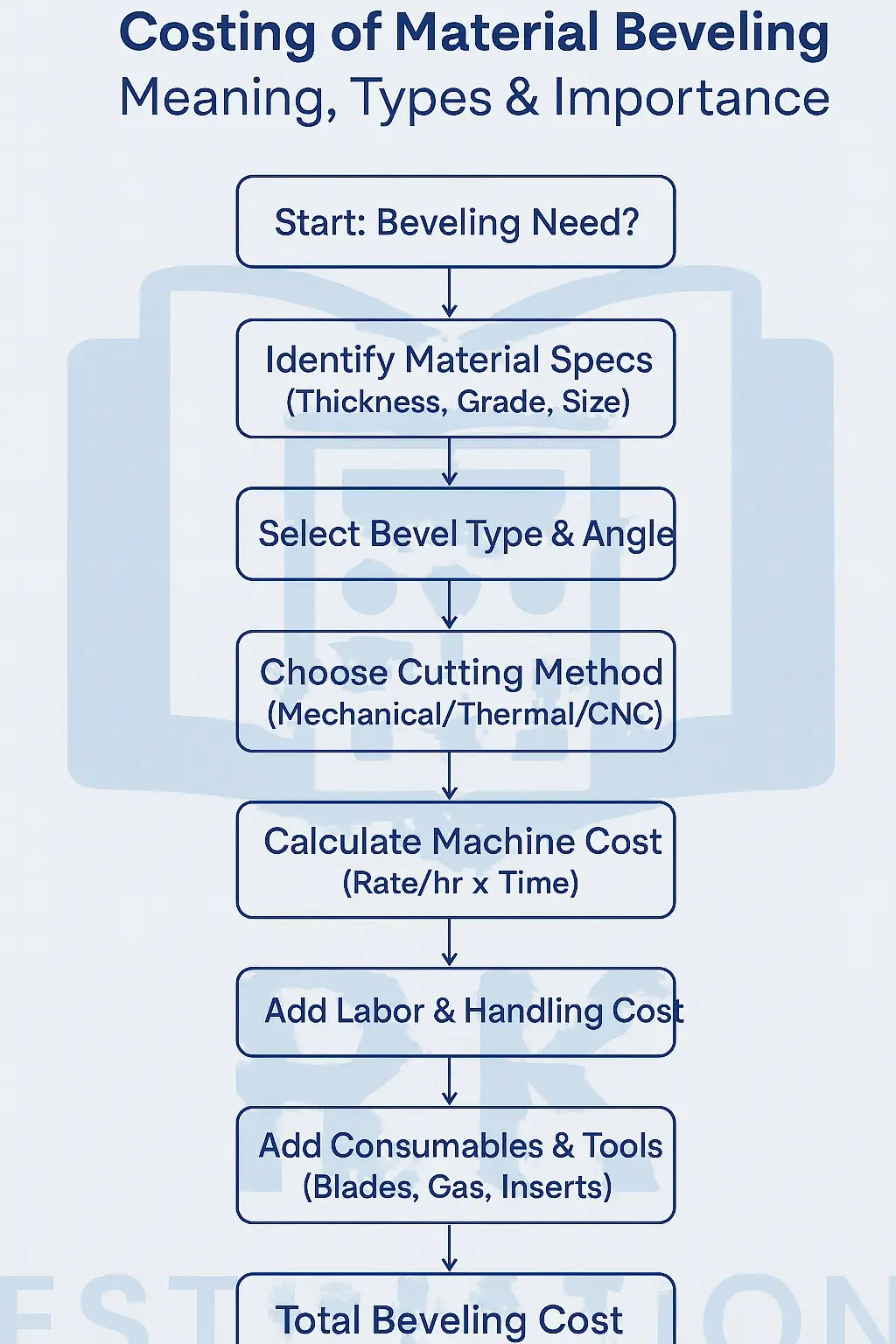

Flow Chart: Costing Process of Material Beveling

Factors Affecting the Cost of Material Beveling

To prepare accurate estimates, costing must be calculated based on a combination of machine, labor, and material parameters:

1. Material Thickness & Grade: Higher hardness or thickness requires stronger tools and more time.

2. Bevel Type & Angle: Complex bevels (J or U) cost more due to machining difficulty.

3. Cutting Method: Each cutting method has a different operating cost.

- Mechanical beveling (milling, grinding)

- Thermal beveling (plasma, oxy-fuel)

- Automated beveling on CNC machines

4. Labor & Operator Skill: Experienced labor increases precision but adds cost.

5. Equipment Wear & Consumables: Blades, inserts, grinding wheels, and gas consumption impact overall cost.

6. Setup Time & Handling: More handling = higher cost, particularly for large plates or pipes.

Why Costing of Material Beveling Matters

Accurate beveling cost estimation helps in:

- Preparing competitive project quotations

- Reducing unwanted fabrication losses

- Optimizing machine utilization

- Improving weld quality and reducing rework

- Ensuring project profitability