Painting is a critical finishing process in manufacturing, fabrication, construction, and industrial maintenance.

It not only enhances the appearance of a product or structure but also provides essential corrosion protection and durability.

To manage projects efficiently, it is vital to understand how painting costs are calculated and what factors influence them.

This guide explains the meaning of painting process costing, common painting methods, and the key cost factors involved.

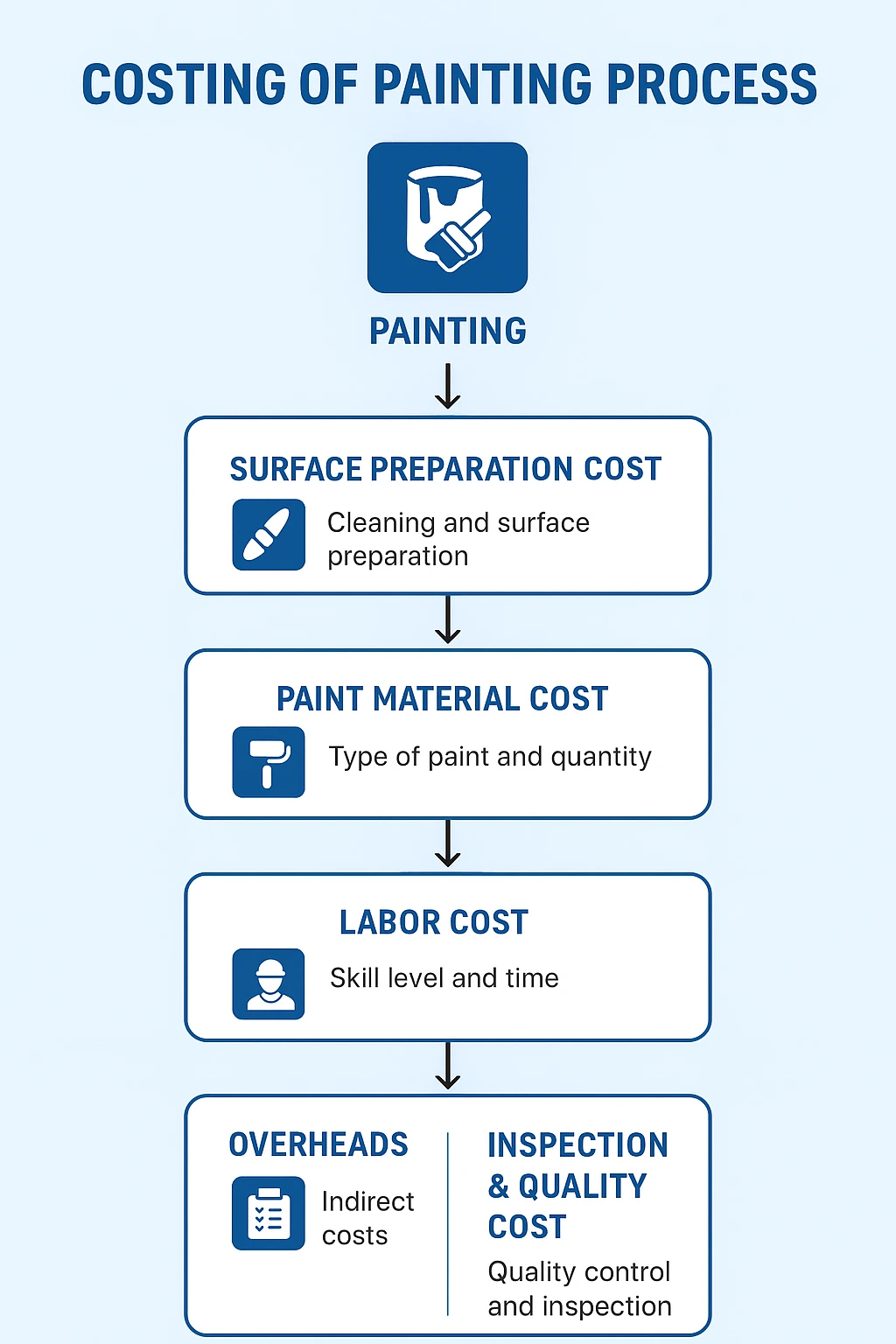

What Is Painting Process Costing?

Painting process costing refers to the systematic estimation of expenses involved in applying paint or coating to a surface.

It includes material, labor, equipment,

surface preparation, and overheads associated with completing a painting job.

The goal is to accurately determine the total cost per square meter (or per unit) so contractors, fabricators, and estimators can deliver competitive and profitable quotations.

Common Painting Methods in Industry

1. Brush Painting

- Used for small areas, touch-ups, or detailed work.

- Low equipment cost but slower productivity.

2. Roller Painting

- Suitable for walls, large flat surfaces, and site work.

- Faster than brush painting and provides uniform coverage.

3. Spray Painting (Airless / Conventional)

- Used for fabrication, pipelines, machinery, automotive, and industrial finishing.

- High productivity and smooth finish; requires skilled workers and controlled conditions.

4. Powder Coating

- Electrostatic application of powder followed by oven curing.

- Durable finish; requires specialized equipment.

5. Dip Coating

- Workpieces are dipped into liquid paint or coating.

- Best for high-volume parts where uniform coverage is needed.

Key Cost Factors in Painting Process

Explanation of Each Component

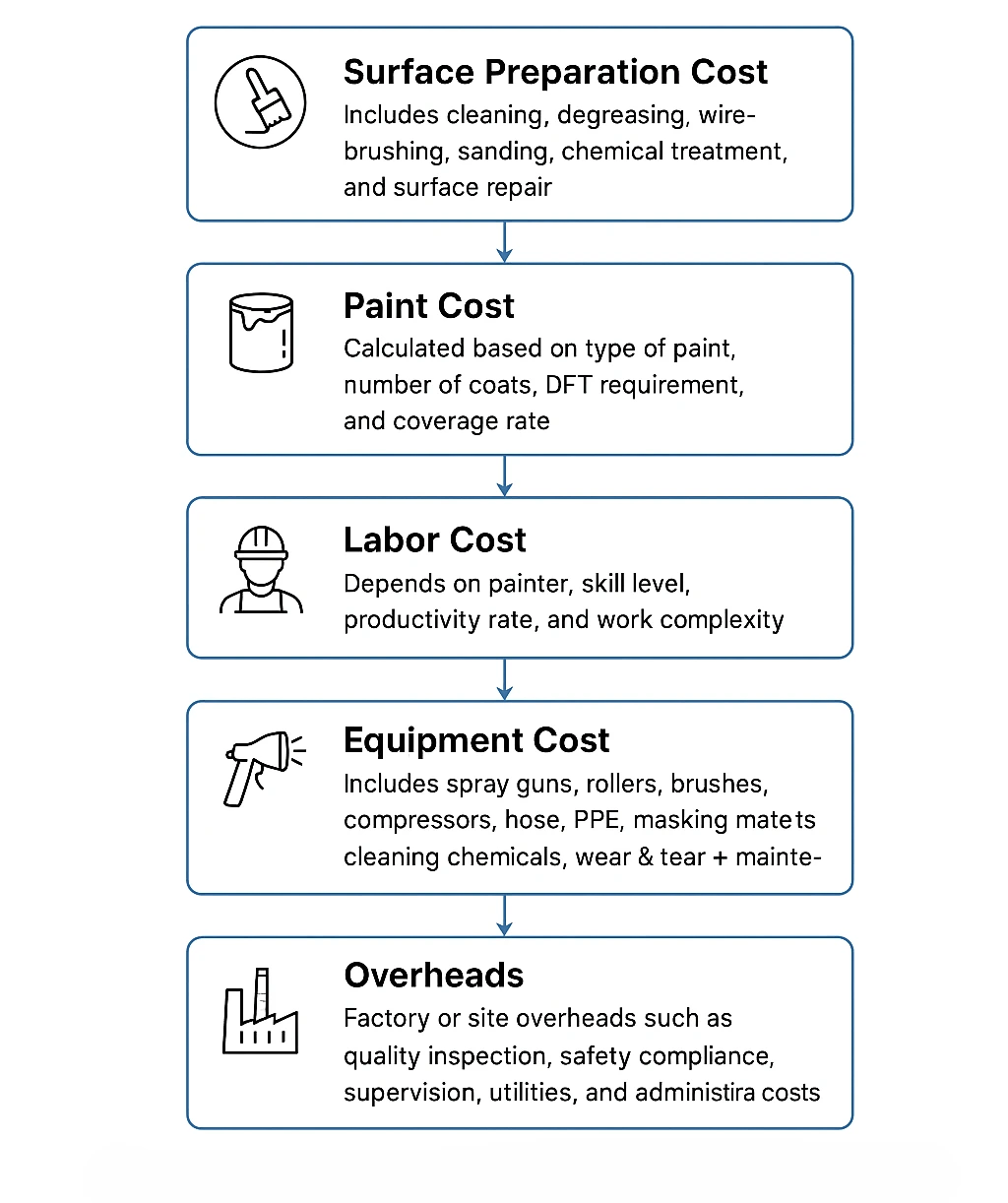

1. Surface Preparation Cost

Surface Preparation Cost includes surface repair process:

- Cleaning,

- Chemical treatment like Degreasing,

- Wire-brushing,

- Sanding and

- Shot blasting

Why it matters: Surface prep often contributes 30–50% of total cost and directly affects coating quality.

Often the most time-consuming part and significantly affects coating performance.

2. Paint Material Cost

Paint Material Cost Calculated based on:

- Type of paint: epoxy, polyurethane (PU), enamel, zinc-rich primer etc

- Number of coats required

- Dry Film Thickness (DFT) requirement

- Coverage rate (m²/litre)

Coating Thickness Requirement (DFT)

- DFT (Dry Film Thickness) specifications affect paint quantity.

- Higher thickness = higher material cost and longer cycle time.

Paint Consumption Factor / Wastage

- Overspray loss in spray painting.

- Absorption in porous surfaces.

- Rework due to defects (runs, sags, dust nibs).

3. Labor Cost

Labor Cost includes preparation, masking, painting and drying/curing time.

Depends on:

- Skill level of painter

- Productivity rate (m²/hour)

- Work complexity (touch-up vs. industrial coating)

4. Equipment & Consumables Cost

Equipment & Consumables Cost includes:

- Spray guns, rollers, brushes

- Compressors, hoses, drying lamps

- PPE, masking materials

- Cleaning chemicals and solvents

- Wear & tear and

- Maintenance expenses.

5. Overheads & Administrative Costs

Factory or Site Overheads & Administrative Costs such as:

- Shop rent

- Supervision, Job planning and reporting.

- Quality inspection and documentation for quality checks.

- Safety compliance

- Utilities (power, air supply)

- Administration costs

- Environmental & Safety Requirements

- Ventilation, dust control, temperature/humidity control.

- Compliance with safety standards adds operational costs.

How to Calculate Painting Cost

To determine the industrial painting cost accurately, use the following standard

Step-by-Step Formula:

Total Painting Cost = Surface Preparation cost + Paint Material cost + Labor cost+ Equipment & Consumables Cost + Overheads

Where:

Surface Preparation Cost = (Total Surface Area × Preparation Cost per m²)

Paint Material Cost = (Total Paint Quantity × Paint Rate)

Labor Cost = (Total Hours × Labor Rate)

Equipment & Consumables Cost = (Total Time × Daily / Hourly Rate of Machines & Tools)

How to Calculate Painting Cost per m²

Painting Cost per m² = (Surface Preparation Cost + Paint Material Cost + Labor Cost + Equipment Cost + Overheads) / Total Painted Area

Painting Cost Calculation Example, If:

- Surface Preparation = ₹12,000

- Paint Cost = ₹8,000

- Labor = ₹15,000

- Equipment = ₹3,000

- Overheads = ₹2,000

- Total Painted Area = 500 m²

Cost per m² = (12,000 + 8,000 + 15,000 + 3,000 + 2,000) ÷ 500

= 40,000 ÷ 500= ₹80 per m²

Conclusion

Understanding the costing of the painting process helps businesses prepare accurate quotations, control project budgets, and avoid unexpected expenses.

By considering paint type, surface preparation, labor productivity, equipment, and environmental conditions, estimators can achieve more reliable and competitive cost calculations.