Material cost is one of the largest components in any construction, fabrication, or manufacturing project.

Accurate material costing

helps in preparing competitive quotations, reducing wastage, and improving

project profitability.

This guide explains how to calculate the landed material cost at your factory or site with simple steps, examples and key cost factors you should never miss.

Try Our Free Online Cost Estimation Calculator

Instantly calculate material, labor, overhead, GST, and profit for your project with RK Estimation tools.

What is Material Cost?

Material cost refers to the total cost involved in purchasing, transporting, handling, storing, testing, and using materials required for a project or product.

It includes both direct materials (raw materials) and indirect materials (consumables & supporting items).

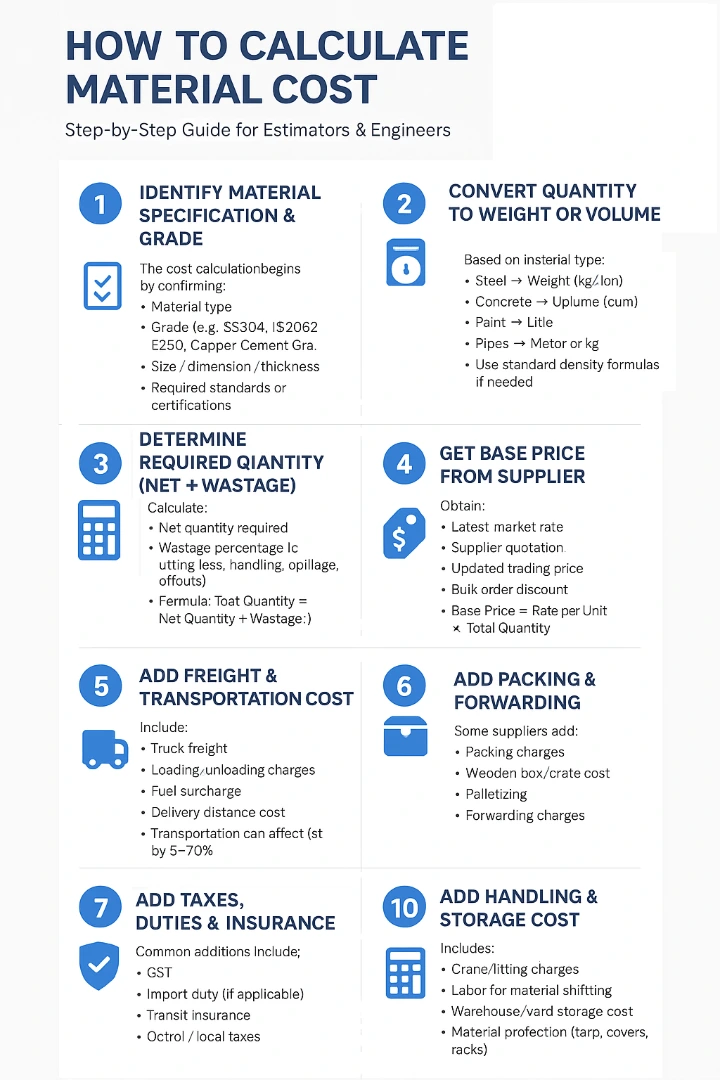

How to Calculate Material Cost? (Step-by-Step)

Below are Step-by-Step method to calculate the true landed cost of materials at your factory or site.

1. Identify Material Specification & Grade

Why important?

Identify Material Specification & Grades in important as different grades and thicknesses change material price drastically.

Below are the main factors to identify material specification & grades and the cost calculation begins by confirming:

- Material type and Grade: Chemical Composition, Mechanical Properties, Physical Properties (e.g.IS2062 E250, Copper, Cement Grade)

- Manufacturing / Forming Requirement

- Required standard codes or Specifications

- Dimensional Requirements: Size-length, width and thickness

- Service Environment

- Required Certifications

- Availability in Market

- Cost Consideration

Example: Consider Material: IS2062 E350 Steel Plate for Fabricated and welded steel Structure with Plate Length =1250mm Width=2265mm Thickness=45 Qty-1 no.

2. Convert Quantity to Weight or Volume

Based on identified material type and size Convert required Quantity to Weight or Volume:

- Steel → Weight (kg/ton)

- Concrete → Volume (cum)

- Paint → Litre

- Pipes → Meter or kg

Formula: The standard formula used worldwide:

Weight (kg) = (Length (mm) × Width (mm) × Thickness (mm) × Density (kg/m³))/1000000000

Where, For steel density ≈ 7850 kg/m³

For above example of IS2062 E350 Steel Plate Length =1250mm Width=2265mm Thickness=45 Qty-1 no.

weight = (1250×2265×10×7850)/1000000000 = 1000 kg

3. Determine Required Quantity (Net + Wastage)

Determining the required quantity of materials is a critical step in material planning and accurate cost estimation.

It ensures that you procure enough material for the job while controlling waste and avoiding shortages.

To determining the required quantity of materials, we need to calculate below:

Net quantity required (This is the precise amount of material required to complete the work as per drawings, BOQ, and specifications.

Wastage percentage (cutting loss, handling loss, spillage, offcuts)

Formula: Total Quantity = Net Quantity + Wastage (%)

Example: Net steel required = 1,000 kg and Wastage = 5%

Total Quantity = 1000 × 1.05 = 1050 kg

4. Get Base Price from Supplier

To get base price or Ex-works price from supplier obtain:

- Latest market rate

- Supplier quotation

- Updated trading price

- Bulk order discount

Formula: Base Price = Rate per Unit × Total Quantity

Example: Material Rate: ₹50/kg

Base Price: 1050 × 50 = ₹52,500

5. Add Freight & Transportation Cost

Freight and Transportation cost include below:

- Truck freight

- Loading/unloading charges

- Fuel surcharge

- Delivery distance cost

Transportation can affect cost by 5–20%.

6. Add Taxes, Duties & Insurance

Common Taxes, Duties & Insurance includes:

- GST

- Import duty (if applicable)

- Transit insurance

7. Add Packing & Forwarding

Some suppliers add packing and forwarding cost to protect materials from damage during shipping and depends on customer requirement:

- Packing charges

- Wooden box/crate cost

- Palletizing

- Forwarding charges

8. Add Testing & Certification Cost

Testing and certification cost Required for industries like oil & gas, marine, structural steel. these include charges for:

- Mill test certificate (MTC)

- Third-party inspection (TPI)

- Material chemical testing

- Ultrasonic / hardness tests

9. Add Handling & Storage Cost

Major handling and storage cost includes:

- Crane/lifting charges

- Labor for material shifting

- Warehouse/yard storage cost

- Material protection (tarp, covers, racks)

Final Material Cost Calculation

Below formula used to calculate final landed material cost of a materials at your factory or site:

Final Material Cost = (Base Price + Freight + Taxes + Packing + Testing + Handling & Storage + Misc Costs)

Sample Example Calculation

Material: IS2062 E350 Steel Plate

Net Quantity: 1000 kg, Wastage: 5% → 50 kg, Total Qty: 1050 kg

Material Rate: ₹50/kg, Base Price: 1050 × 70 = ₹52,500

Freight: ₹3,000

Packing: ₹1,000

GST: 18% = ₹13,230

Handling: ₹1,500

Final Landed Material Cost = ₹52,500 + 3,000 + 1,000 + 13,230 + 1,500 = ₹71,230

Conclusion

Knowing how to calculate material cost helps avoid budget overruns, improves procurement planning, and ensures accurate costing for tenders and estimates. Following the step-by-step method above ensures you never miss any hidden cost.