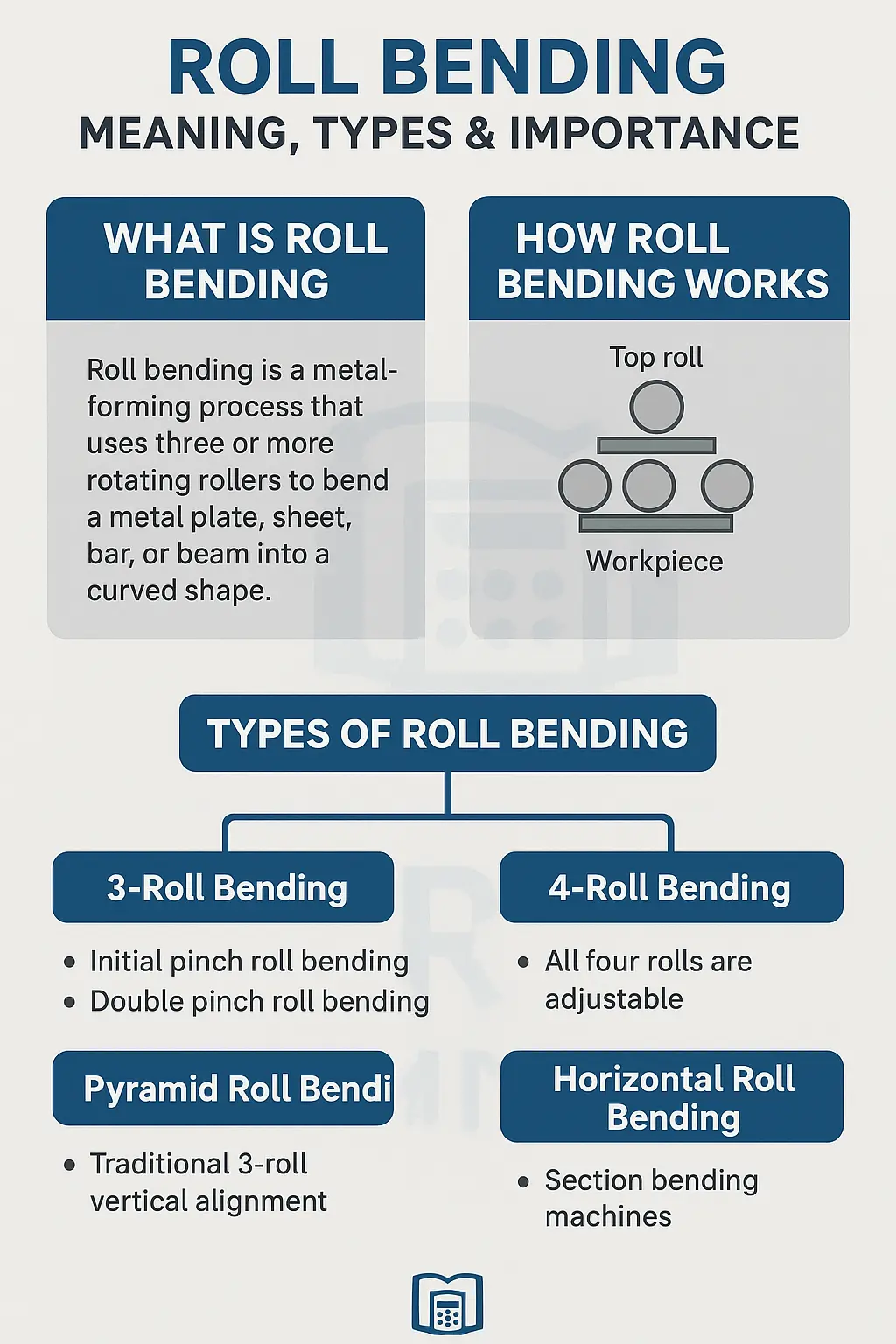

What is Roll Bending?

Roll bending is a metal-forming process that uses three or more rotating rollers to bend a metal plate, sheet, bar, or beam into a curved shape. The rollers apply mechanical force to gradually deform the workpiece into the desired radius.

It widely used in manufacturing, fabrication, and construction industries.

Roll bending produces smooth and controlled curve like curved steel beams, cylindrical shells, tank bodies or pipe coils which making it suitable for both light-gauge sheet metal and heavy structural steel applications.

For cost estimators and engineers, understanding roll bending is vital because it directly affects project cost, fabrication time, and structural quality.

It is commonly used for bending of Below Type of Metal:

- Steel plates

- Aluminum sheets

- Pipes and tubes

- Structural sections (I-beams, channels, angles)

- Hollow sections (RHS, SHS)

- Stainless steel coils

How Roll Bending Works

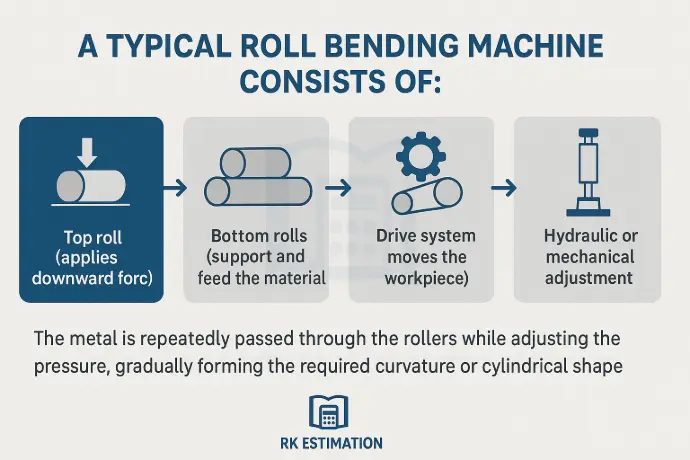

A typical

roll bending machine consists of: Top roll, Bottom rolls, Drive system and Hydraulic or mechanical

adjustment

Types of Roll Bending

Roll bending machines are classified based on their roller arrangement, mechanism, and bending capability.

1.Three-Roll Bending (The most widely used type)

- Two bottom rolls pinch the material

- Top roll bends it

- Suitable for thin to medium plates

- Requires pre-bending to reduce flat ends

- Both top and bottom rolls adjust

- Allows pre-bending at both ends

- Ideal for cylindrical shells, cones, large diameter pipes

a. Initial Pinch Roll Bending (3-Roll)

b. Double Pinch Roll Bending (3-Roll Double Pinch)

2. Four-Roll Bending

- Most advanced and efficient system

- All four rolls are adjustable

- Can complete pinching, rolling, and pre-bending in one setup

- Excellent for heavy plates, high accuracy, and automated production

3. Pyramid Roll Bending

- Traditional 3-roll vertical alignment

- Used for heavy structural sections

- Mainly applied in construction beam bending & large radius rolls

4. Horizontal Roll Bending (Section Bending Machines)

They use strong hydraulic pressure and large rollers for bending heavy structural shapes. These machines bend:

- Beams

- Channels

- Angles

- Tubes

- Pipes

- Hollow sections

5. Planetary or Variable Geometry Roll Bending

- Rollers can rotate and shift dynamically

- Suitable for thick materials

- Allows bending large radii with improved precision

Applications of Roll Bending

Wherever cylindrical, conical, or curved shapes are needed, roll bending is essential. Roll bending is used in various industries, including:

- Pressure vessel manufacturing

- Oil & Gas pipelines

- Shipbuilding

- HVAC ducts

- Construction & infrastructure

- Storage tanks

- Automobile and aerospace components

- Fabrication of silos, boilers, chimneys

Key Factors Affecting Roll Bending Cost which a Cost estimators must consider

- Material thickness & grade – Tougher materials need more force

- Bending radius – Smaller radius = more passes = higher cost

- Roll setup time – Tooling and machine adjustments

- Pre-bending requirement – Reduces flat ends but adds cost

- Machine capacity – Larger machines = higher operating cost

- Labor & skill level – Skilled operators ensure precision

- Deflection control – Shape accuracy impacts finishing cost

Roll Bending Cost Factors Explained – Materials, Machines & Labor: Click below Button

Roll Bending Cost Factors Explained

Importance of Roll Bending

1. Precision Shaping for Manufacturing: Roll bending produces accurate curvatures essential for structural integrity in tanks, pipelines, and vessels.

2. High Efficiency & Repeatability: Ideal for mass production with consistent results.

3. Smooth, Uniform Curves: Reduces stress concentrations and material defects.

4. Wide Material Compatibility: Works with mild steel, stainless steel, aluminum, copper, and alloy materials.

5. Reduced Material Waste: Controlled forming ensures minimal wastage, improving overall project cost.

6. Essential for Modern Infrastructure: From metro stations to industrial storage tanks, roll bending is critical to today’s engineering needs.

Conclusion

Roll bending is a vital metal-forming process that combines precision, efficiency, and versatility. By understanding its meaning, types, applications, and importance, engineers, fabricators, and cost estimators can plan projects more effectively, reduce material waste, and achieve high-quality results.